Virtual Swatchbook

Selection of a Roll Pattern

The selection of a roll pattern for a specific laminate product depends upon numerous factors, as well as the combination of those factors. Some of the key inputs are:

- Types of raw materials

- Thermoplastic vs. non-thermoplastic

- Non-woven, fabric, film, paper, netting

- Bulky vs. thin

- Soft vs. stiff

- Elastic vs. rigid

- Weight of raw materials

- Consistency of quality of raw materials

- Number of layers and order of layers top to bottom

- Performance requirements of laminate in the end use application

- Aesthetic impact on the finished material

Relying upon decades of experience and working together with you, the technical team at Beckmann Converting can recommend the roll pattern(s) that have the best potential for meeting your program goals.

Our selection of laminating roll patterns enable high quality bonding results for every application. Browse through our Virtual Swatchbook of options to find which best fits your needs!

Receive a supplemental Swatchbook showing each roll pattern on actual textile laminates! Simply go to https://www.beckmannconverting.com/resources/needs-assessment-form/, submit your name and mailing address, and check the box just below that section to request a Swatchbook.

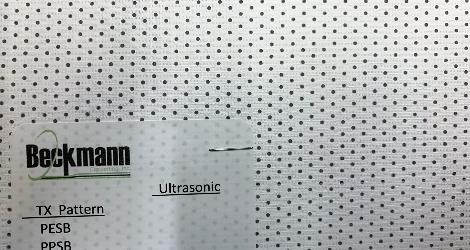

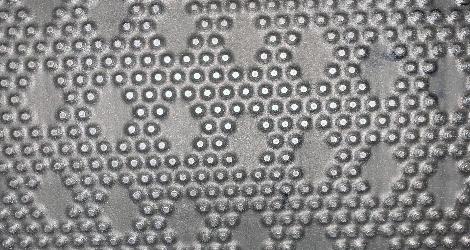

'TX' Roll Pattern

The “TX” design is the busiest of our traditional round pin dot roll patterns. With close pin spacing and low pin height, it is most suitable for lightweight laminates such as 2 or 3 layer wiper products.

'TX' Specification Sheet

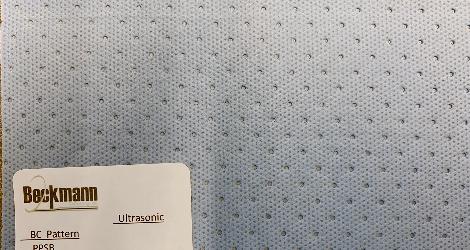

Download PDF'BC' Roll Pattern

The “BC” design is more open in pattern than the TX roll. At a bonded area about 3% of the total area of the laminate, it provides good characteristics for medium weight laminates such as filtration media and construction materials.

'BC' Specification Sheet

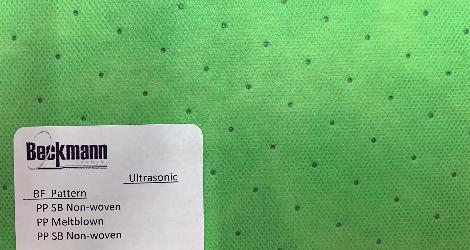

Download PDF'BF' Roll Pattern

The “BF” design is the most open of our pin dot roll patterns and delivers a bonded area of about .5% of total area of the laminate. Although the inter-ply adhesion of the laminate is limited, the BF pattern is effective on more critical filtration media and heavier weight construction materials.

'BF' Specification Sheet

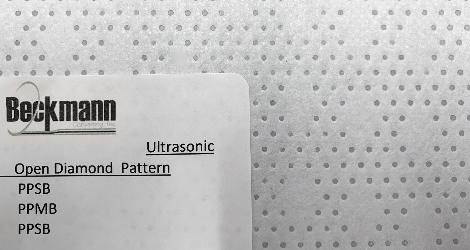

Download PDF'Open Diamond' Roll Pattern

The unbonded areas of the “Open Diamond” design creates interesting surface texture and patterns for certain applications. It is effective in light to medium weight composites that include such applications as knitted and nonwoven wipe products and certain filtration media.

'Open Diamond' Specification Sheet

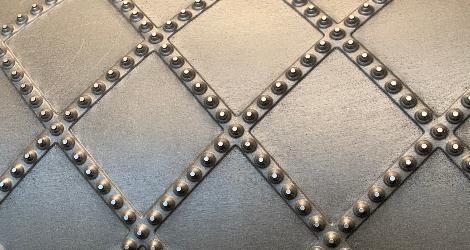

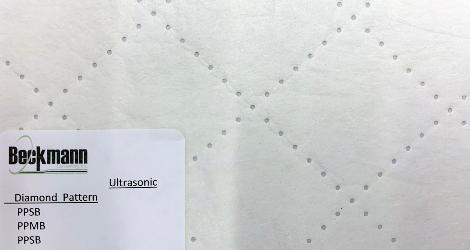

Download PDF'Large Diamond' Roll Pattern

Characterized by large open areas inside the diamond shapes, the Large Diamond roll pattern is a good option for medium to heavy weight laminates. It has been used for absorbent materials for environmental applications and heavier filtration media packages.

'Large Diamond' Specification Sheet

Download PDF'BK' Roll Pattern

The “BK” roll pattern delivers a high bonded area at about 9% of total area of the laminate. It is used for light to medium weight laminates including car cover products. It is also used for seaming and edge sealing applications where a “bonding lane” is the goal rather than full cross web bonding.

'BK' Specification Sheet

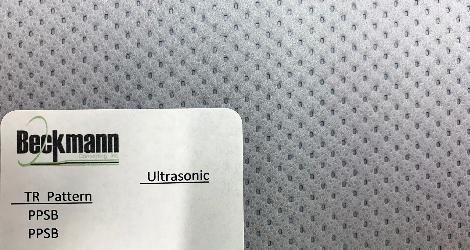

Download PDF'TR' Roll Pattern

The “TR” design is similar to the BK pattern but has more and smaller rectangular dots. It is most appropriate for lightweight laminates such as protective apparel and wipes.

'TR' Specification Sheet

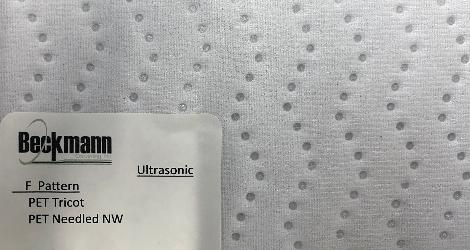

Download PDF'F' Roll Pattern

Characterized by wavy lines of round pin dots, the “F” pattern has large weld windows and is suitable for medium and heavy weight laminates such as reusable incontinence pads, diaper materials, and edge sealing in the machine direction.